Looking to reduce condensation & improve circulation in your container? Check out our three different ventilation options:

The pre-installed container vents. Portable storage containers are normally equipped with standard, pre-installed vents. These are passive vents that are triple-screened to prevent insects from getting inside. Additionally, these vents account for pressure variations that tend to occur when the weather changes. Most containers come with one vent on each side, one by the door, and another on the opposite end. While these vents don’t encourage air flow, they often take care of most of your ventilation needs.

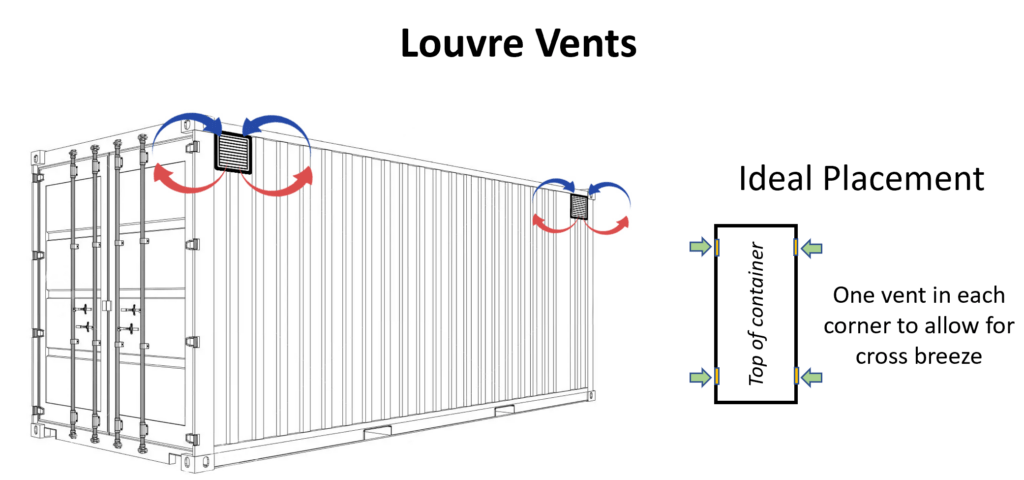

Louvered (side) vents. If you’re looking to combat excessive moisture inside your 10 foot Storage Container, 20 foot Storage Container, 40 foot container or 40′ high cube container, we offer Louvered vents that provide increased airflow and ventilation. These vents are especially useful in situations where moisture and heat build-up are a concern. The temperature inside a container can rise significantly during periods of high ambient temperatures—especially when the container is exposed directly to the sun. In such cases, ensuring a proper system of air exchange is crucial to prevent condensation and heat-related damage.

Louver vents

• Heavy duty construction

• Used for flush mounting

We recommend installing two to four Louvered vents placed on opposite ends and sides of the container to create a cross breeze and encourage air circulation. This setup helps improve air quality by allowing fresh air to enter while pushing out stagnant air and odors. Louver Vents also come with a built-in screen to keep insects out, and are constructed for heavy-duty, flush-mount installation. The opening of the Louver Vent is 12″ x 12″, and the total frame size is 14″ x 14″. Be sure to leave space around the vent to allow for proper airflow.

For applications where the vent might be exposed to frequent contact—such as at schools or public areas where someone might kick or damage the lower portion of the vent—it is recommended to upgrade to a purpose-built steel vent with a backing screen for added durability and protection.

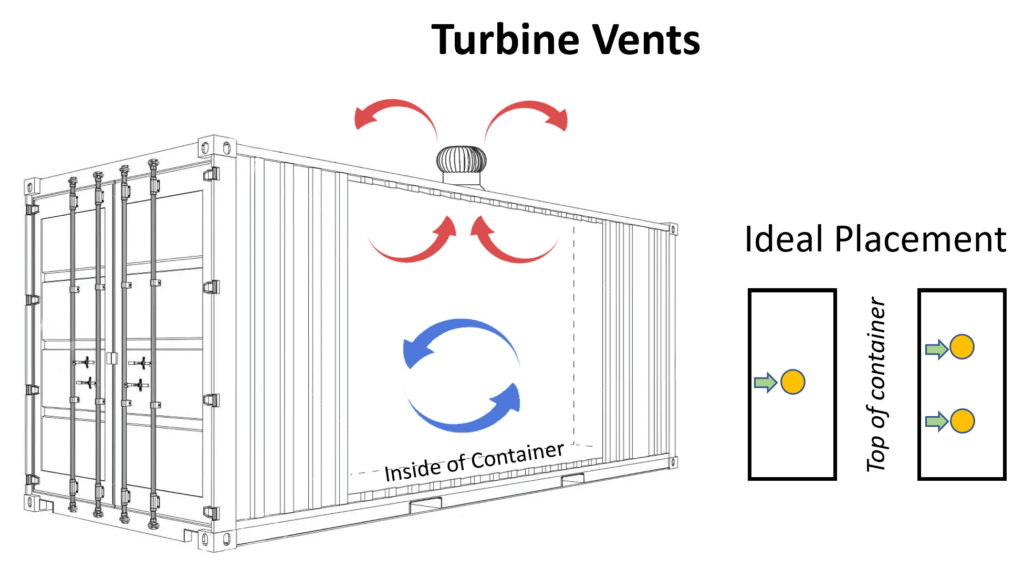

Turbine vents. Finally, we offer turbine (whirlybird) vents, which will be cut into the roof of your 10’/20’/40′ container. Turbine vents use wind energy to create airflow and exhaust stale air, heat and moisture from the container’s interior. The only downside to these turbine vents is that during snow-melt, the turbine vent can freeze shut, but clearing the snow off the roof will help lessen this impact. Turbine vents are the most effective options for circulating air inside of the container. Our turbine vents are made of all aluminum construction, with 21 air foils with rolled edges to deflect water, permanently lubricated with upper and lower ball bearings to ensure long life and low maintenance. They are heavy-duty and durable, tested to withstand 147 mile-per-hour wind. Turbine vents are only available for leases of more than a year or container sales.

Turbine Vent

• All aluminum construction

• 21 air foils with rolled van edges to deflect water

• Permanently lubricated with upper and lower ball bearings to ensure long life and low maintenance

• Tested to withstand 147 mile per hour wind

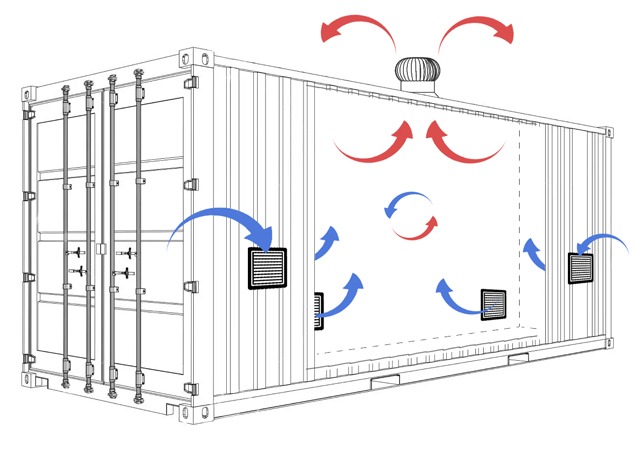

Optimized Airflow: Turbine & Louver Vent Combo

For improved ventilation, consider combining turbine vents with louver vents. Turbine vents help draw warm air and moisture out of your container using wind power, while louver vents allow fresh air to enter for better circulation. This setup can help reduce condensation and improve airflow, especially in humid or high-temperature environments. To maintain effectiveness, it’s important to keep vents free of obstructions, such as dust, debris, or stored items blocking airflow. Regularly checking and clearing the vents can help ensure continuous ventilation and a fresher interior.

| Feature | Regular Ventilation | Turbine Ventilation | Louver Ventilation |

|---|---|---|---|

| Size | 2.5″ x 8″ | 13″ x 13″ | • 12″ × 12″ (Opening) • 14″ × 14″ (Including frame) |

| Material & Design | • Steel • Mounted on side of container. | • All aluminum construction for durability and resistance. • 21 air foils with rolled edges to deflect water. • Mounted on roof of container. | • Steel (Heavy-duty construction for enhanced durability and resistance) • Staggered design to prevent water from entering container. • Mounted on side of container. |

| Airflow | Minimal airflow | Maximum (Utilizes wind energy to create airflow, exhaust stale air, heat, and moisture) | Good (Provides increased airflow to combat excessive moisture, with options for cross breeze) |

| Benefits | • Handles pressure variations. • Low maintenance. • Enhanced airflow. | • Maximizes airflow using wind energy. • Durable and withstands high winds. • Low maintenance with permanent lubrication. | • Good airflow with options for cross breeze. • Heavy-duty and bug-proof construction. • Designed to improve air quality significantly. |

| Downsides | May not be sufficient for high moisture environments. | • Can freeze in winter, affecting functionality. • Minimal wind to operate effectively. | • Requires two or more vents for effective cross breeze. • May require more vents for large containers. |

For information on heating and AC units, please visit our Office Containers & Office Trailers pages

Eagle Leasing offers a wide variety of container customizations. For more information or questions about our containers customized with ventilation call 1-800-438-3245 or email us your request.